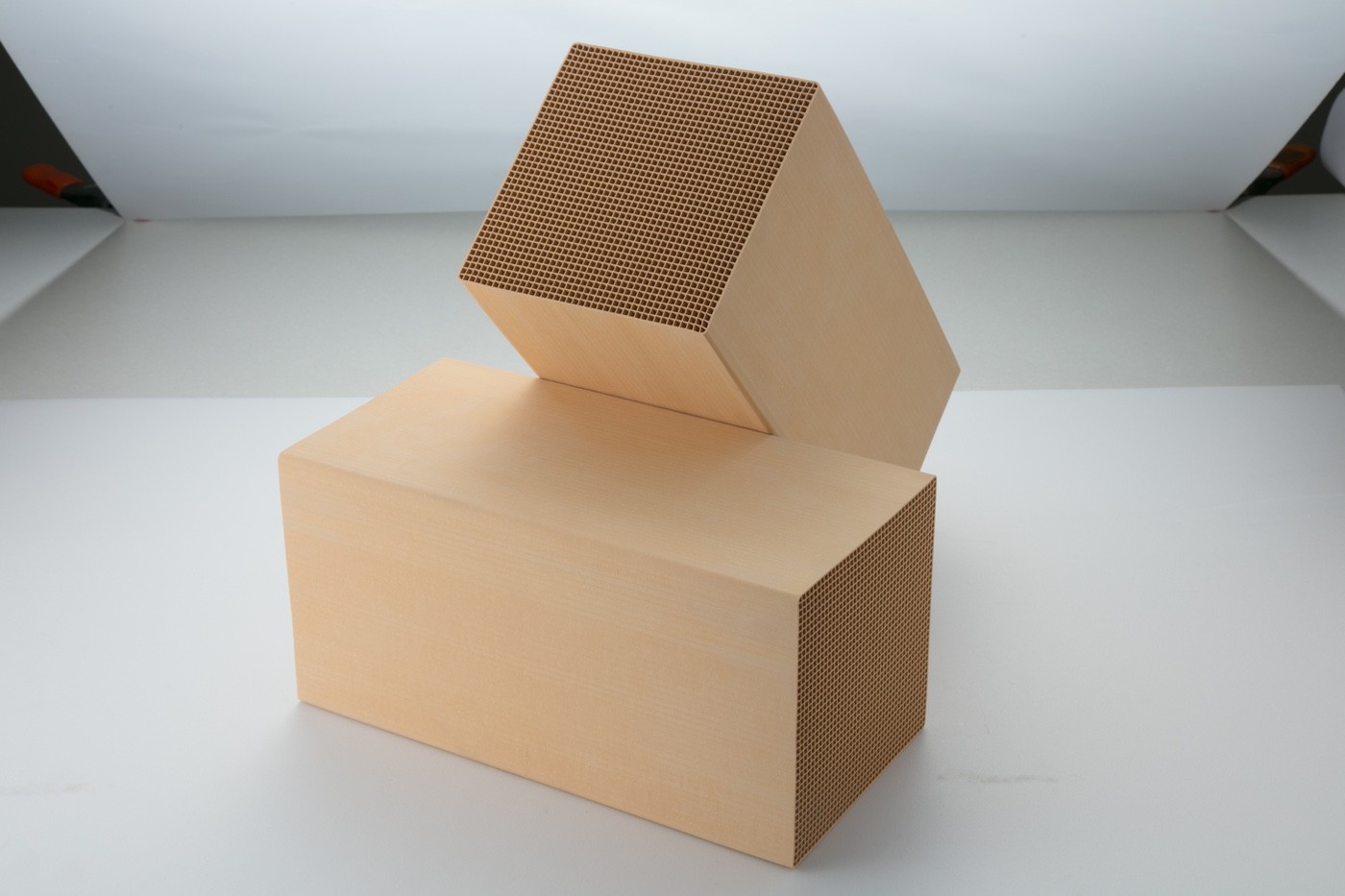

Honeycomb SCR

Honeycomb SCR catalysts feature a structure with uniformly arranged hexagonal single channels, ensuring consistent gas flow and stable performance. They maximize energy efficiency through low-pressure loss and provide long-term stable operation with high mechanical strength.

The honeycomb SCR catalyst maintains consistent reaction performance through its uniform channel structure while enhancing energy efficiency with low-pressure loss. Its high mechanical strength and durability guarantee stable performance even during long-term operation, and its design is optimized for large facilities, enabling reliable operation.

Application areas

Primarily applied to NOx reduction facilities in power plant exhaust gas treatment systems and large industrial facilities. It delivers excellent performance in environments requiring stable gas processing. Especially suitable for facilities requiring long-term continuous operation, providing consistent and reliable emissions reduction effects.

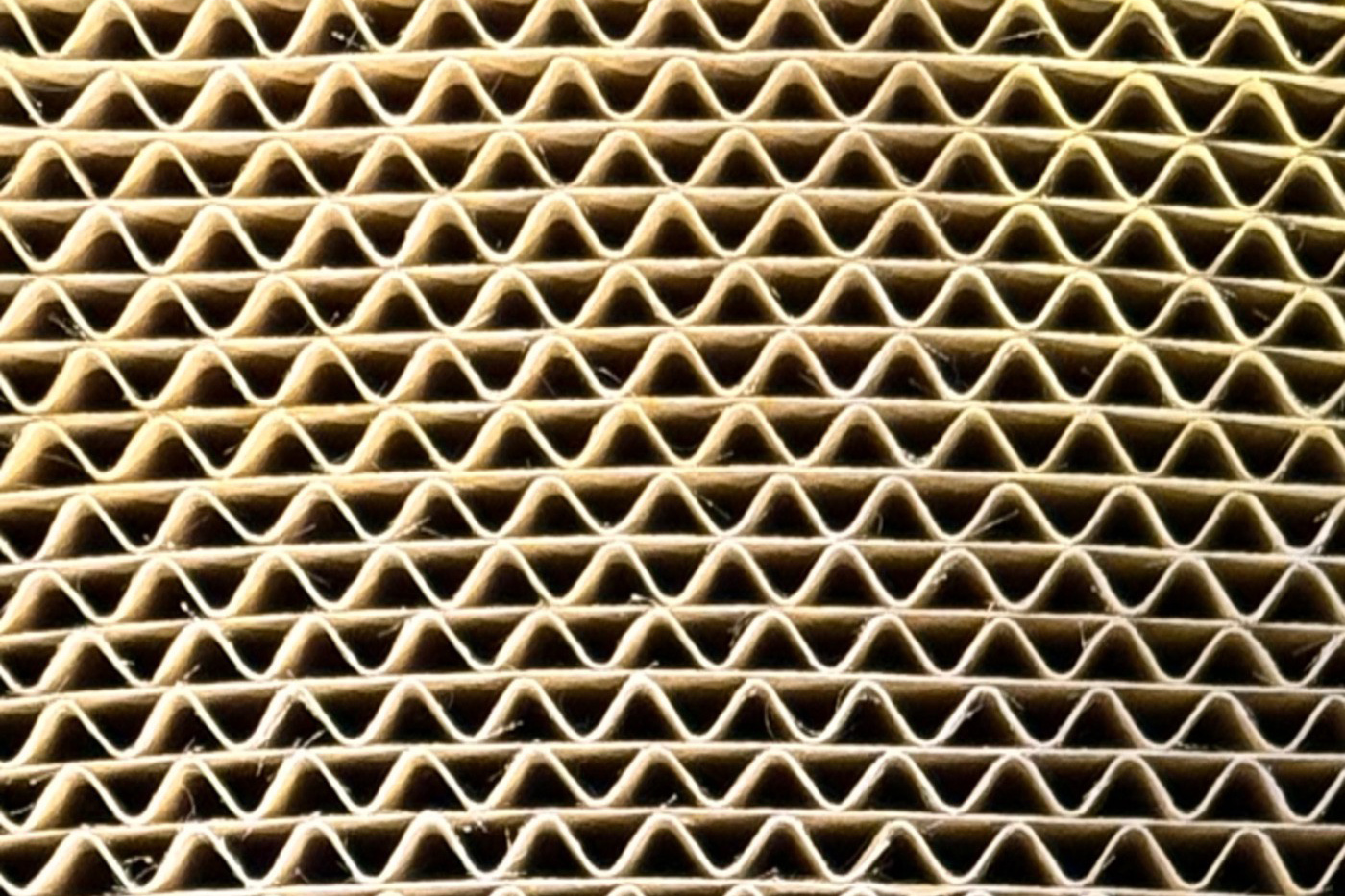

Corrugated SCR

Corrugated SCR catalysts are constructed by layering wave-shaped metal plates, providing a large reaction surface area and an efficient reaction structure. The lightweight design allows for easy installation, offering flexibility to adapt to various installation environments.

The corrugated SCR catalyst achieves high purification efficiency through its broad reaction surface area and flexible design, making it adaptable to diverse installation conditions. Its lightweight structure simplifies installation and maintenance, while the compact design ensures excellent space efficiency.

Application Areas

Optimized for marine SCR systems and industrial facilities with space constraints, delivering exceptional performance even in environments requiring high-efficiency treatment. Particularly well-suited for facilities requiring frequent maintenance, enabling convenient management and efficient operation.

Heesung's Specialized Customer Technical Support

We do not simply sell catalyst products. Heesung Catalysts provides tailored technical support to ensure customers fully benefit from our specialized catalytic technologies. By providing optimal catalyst conditions to ensure that our catalysts perform at their best in a variety of processes. With over 40 years of accumulated experience, we enable improved catalyst performance, longer lifespan, and enhanced stability.

The technology behind Heesung Catalysts

The Heesung Catalyst Difference

Partnership for a sustainable future

Heesung Catalysts supports achieving greenhouse gas reduction goals through close collaboration with customers. Our expert team analyzes your specific requirements and proposes the optimal solutions to build a sustainable future together.

If you need innovative solutions to reduce greenhouse gases, consult Heesung Catalysts. Together, we can create a cleaner planet.