Next-Generation Clean Energy: Hydrogen Production Catalyst

Hydrogen is a key energy source for achieving a carbon-neutral society as a candidate to replace fossil fuels in the future. As an eco-friendly energy source with zero pollutant emissions, hydrogen is expected to account for about 18% of the world’s energy demand by 2050. Heesung Catalysts offers a variety of catalysts and solutions across the hydrogen value chain, including SMR (Steam Methane Reforming) catalysts for traditional hydrogen production, system catalysts, and eco-friendly hydrogen production catalysts for fuel cells and water electrolysis.

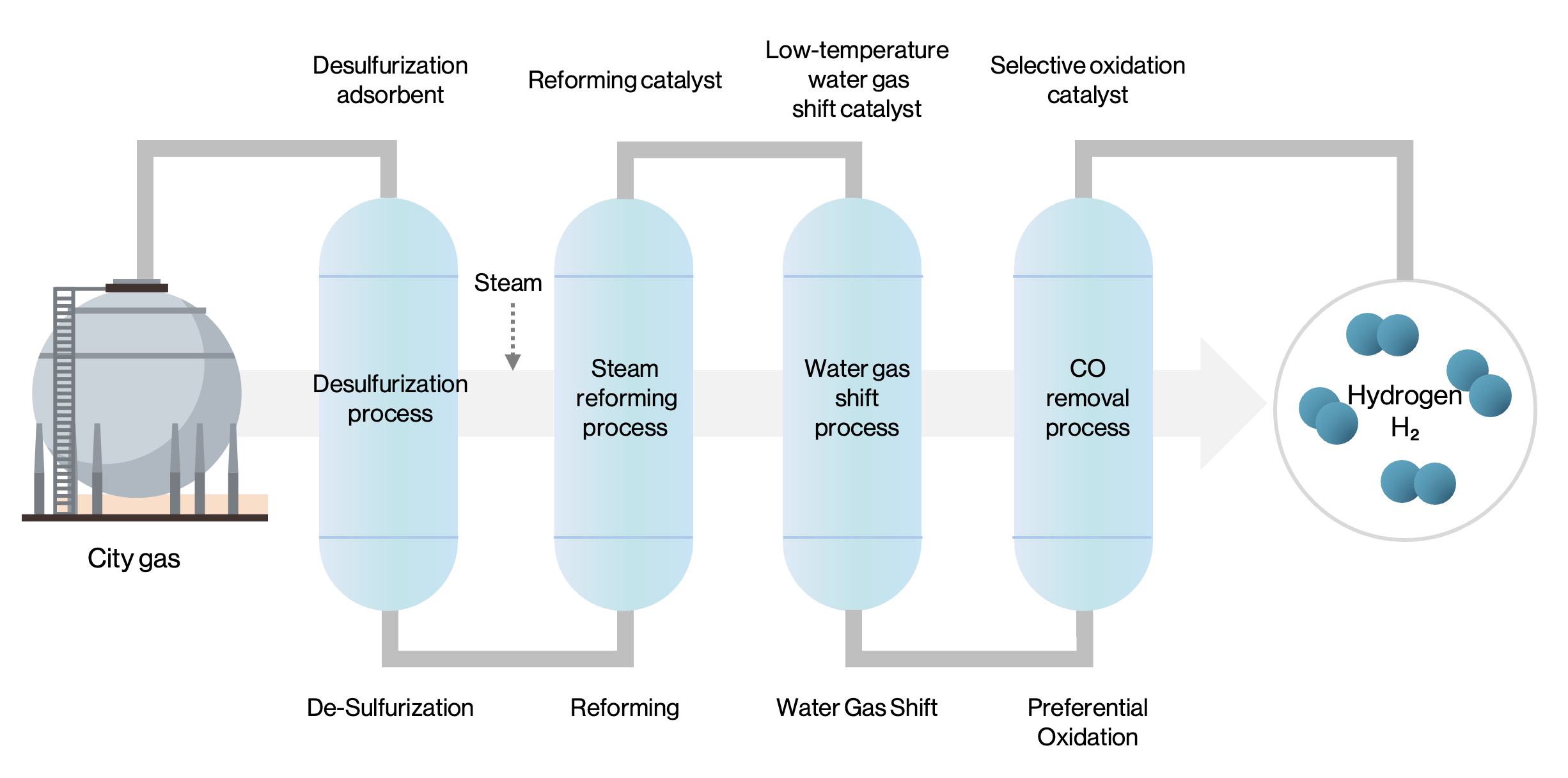

General Process of Fuel Reforming Systems

Applications and products for hydrogen production catalysts

| Process | Reaction formula | Catalyst type | |

|---|---|---|---|

| High-temperature desulfurization | HDS | C4H8S + 2H2 → H2S + C4H10 | Precious Metal, Base Metal |

| ADS | H2S+2MxOy →2H2O+MxS | Base Metal | |

| Low-temperature desulfurization | ADS | H2S + M-O → H2O + M-S | Base Metal |

| Reforming | LNG Reforming | CH4 + H2O → CO + H2 | Precious Metal, Base Metal |

| HC Pre-Reforming | CnH2n+2 + nH2O → nCO + (2n+1)H2 | Base Metal | |

| Bio-gas Reforming | CH4 + CO2 → 2CO + 2H2 | Base Metal | |

| CPOX | CH4 + ½O2 → CO + 2H2 | Base Metal | |

| Water gas shift | Low Temp. Shift (LTS) | CO + H2O → CO2 + H2 | Base Metal(Mixed Oxide) |

| CO removal process | PROX | CO + ½ O2 → CO2 | Precious Metal |

Download Decarbonization Catalyst Brochure

Heesung's Specialized Customer Technical Support

We do not simply sell catalyst products. Heesung Catalysts provides tailored technical support to ensure customers fully benefit from our specialized catalytic technologies. By providing optimal catalyst conditions to ensure that our catalysts perform at their best in a variety of processes. With over 40 years of accumulated experience, we enable improved catalyst performance, longer lifespan, and enhanced stability.