Key Technology for Eco-Friendly Hydrogen Transportation: Ammonia Cracking Catalyst

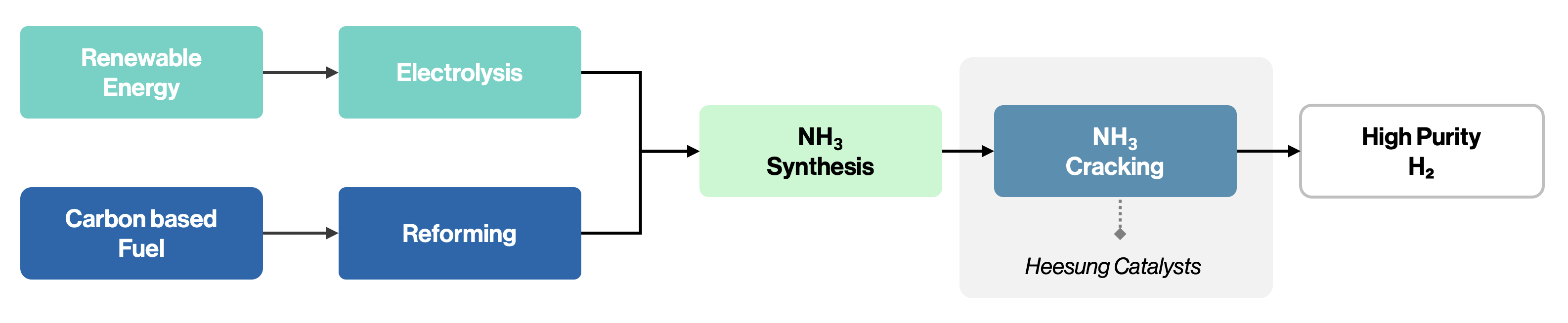

Ammonia is gaining attention as an energy carrier for efficient hydrogen storage. With its high hydrogen storage density, ability to liquefy at ambient temperatures, ease of transport and storage, and compatibility with existing infrastructure, ammonia is a critical component of the hydrogen economy.

Heesung Catalysts provides ammonia cracking catalyst solutions for hydrogen storage, transportation, and utilisation stages, supporting the efficient use of hydrogen. We offer a variety of ammonia cracking catalysts tailored to application areas, including precious metal catalysts for efficient hydrogen conversion in low-temperature environments with limited heat sources and metal catalysts for environments with abundant heat sources, such as power generation.

| Process | Catalyst type | Shape |

|---|---|---|

| High Temperature (500~800℃) | Base Metal (Mainly Ni)/Bi-Metallic (Ni-PM) | Pellet, Sphere |

| Low Temperature (300~500℃) | Precious Metal (Mainly Ru) |

Download decarbonization catalyst brochure

Heesung's Specialized Customer Technical Support

We do not simply sell catalyst products. Heesung Catalysts provides tailored technical support to ensure customers fully benefit from our specialized catalytic technologies. By providing optimal catalyst conditions to ensure that our catalysts perform at their best in a variety of processes. With over 40 years of accumulated experience, we enable improved catalyst performance, longer lifespan, and enhanced stability.