Paraffin Dehydrogenation Catalysts

The dehydrogenation process of paraffins such as propane and butane is one of the important production processes to produce olefins, the basic oils. The performance of the catalyst, especially the conversion rate, selectivity, and lifetime, are the main factors that directly affect the production efficiency. The dehydrogenation catalysts independently developed by Heesung Catalysts can help you improve the quality of the products you produce, increase productivity, reduce costs, and ultimately increase the added value of your production to improve customer profitability.

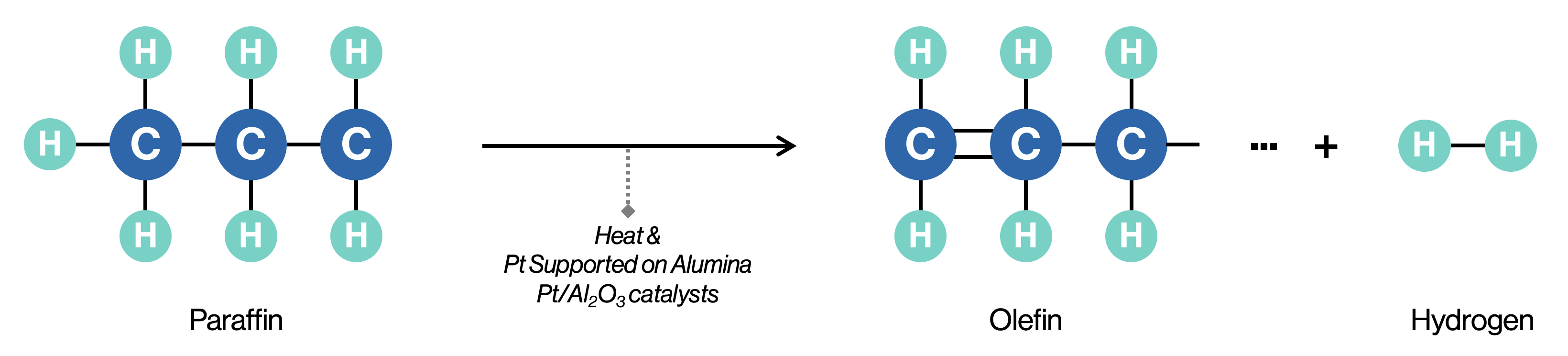

Paraffin dehydrogenation reaction

Key characteristics of rare earth dehydrogenation catalysts

Heesung's Specialized Customer Technical Support

We do not simply sell catalyst products. Heesung Catalysts provides tailored technical support to ensure customers fully benefit from our specialized catalytic technologies. By providing optimal catalyst conditions to ensure that our catalysts perform at their best in a variety of processes. With over 40 years of accumulated experience, we enable improved catalyst performance, longer lifespan, and enhanced stability.