Decarbonizing the Aviation Industry: The Rise of Sustainable Aviation Fuel (SAF)

2025.02.25

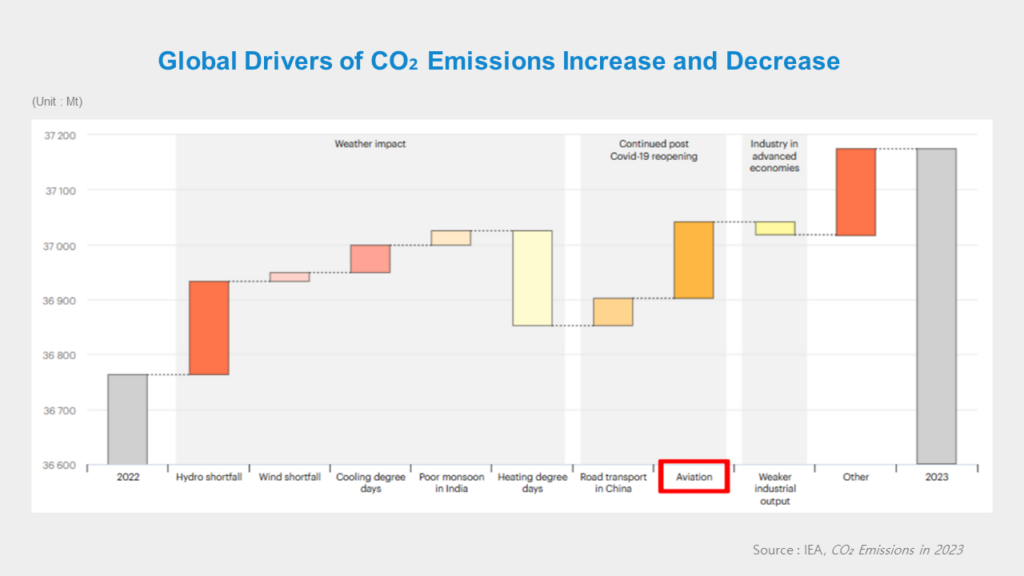

In 2023, global CO₂ emissions from the energy sector increased by approximately 410 Mt (+1.1% YoY), reaching a total of 37.4 Gt. Factors such as China’s post-pandemic economic rebound, recovery in air travel, and climate variations contributed to this rise. Aviation alone accounted for 950 Mt of CO₂ emissions—about 2.5% of global energy-related emissions—showing the fastest growth among all transport sectors from 2000 to 2019.(Figure1)

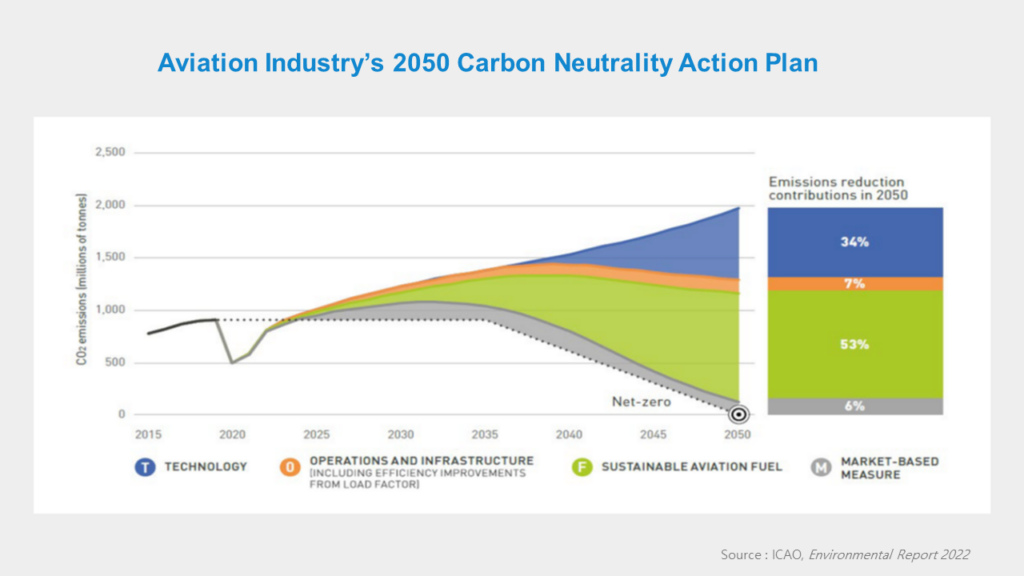

The Aviation Industry’s Carbon Neutrality Roadmap

In response to growing climate concerns, the aviation industry is accelerating decarbonization. The International Civil Aviation Organization (ICAO) proposed a 2050 Net-Zero Action Plan comprising :

- 53% SAF adoption

- 34% technological innovation

- 7% operational efficiency

- 6% carbon offsetting

Among these, SAF has emerged as the most critical solution.

What Is SAF? (Sustainable Aviation Fuel)

SAF (Sustainable Aviation Fuel) is a renewable alternative to traditional jet fuel (Jet A-1). It is produced from feedstocks such as used cooking oil, biomass (agricultural, forestry, and livestock waste), and CO₂-based syngas.

It is chemically similar to fossil-based jet fuel, allowing seamless integration into existing aircraft and fueling infrastructure. According to the International Energy Agency (IEA), SAF can reduce lifecycle carbon emissions by up to 80% compared to conventional fuels.

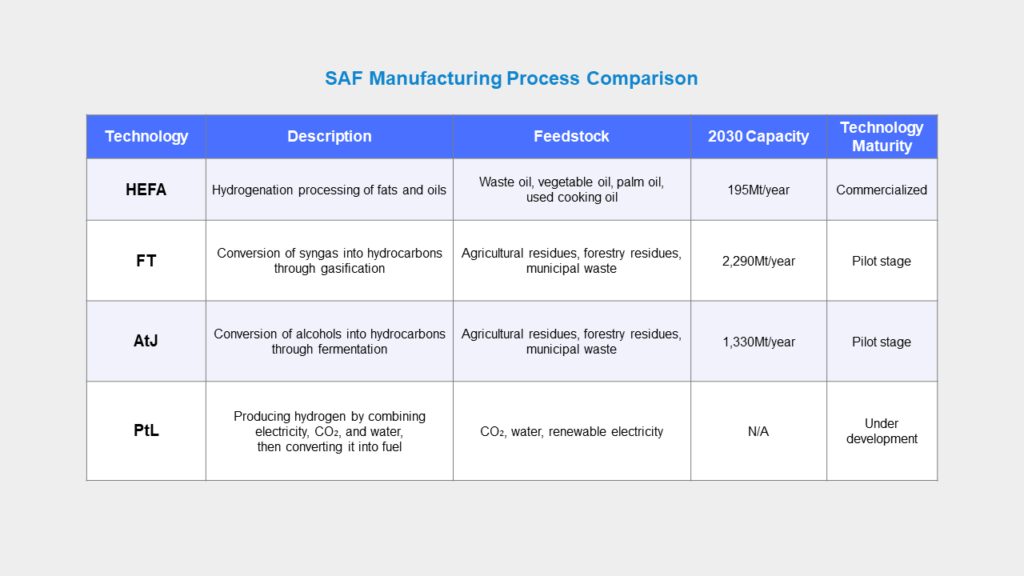

SAF Production Pathways

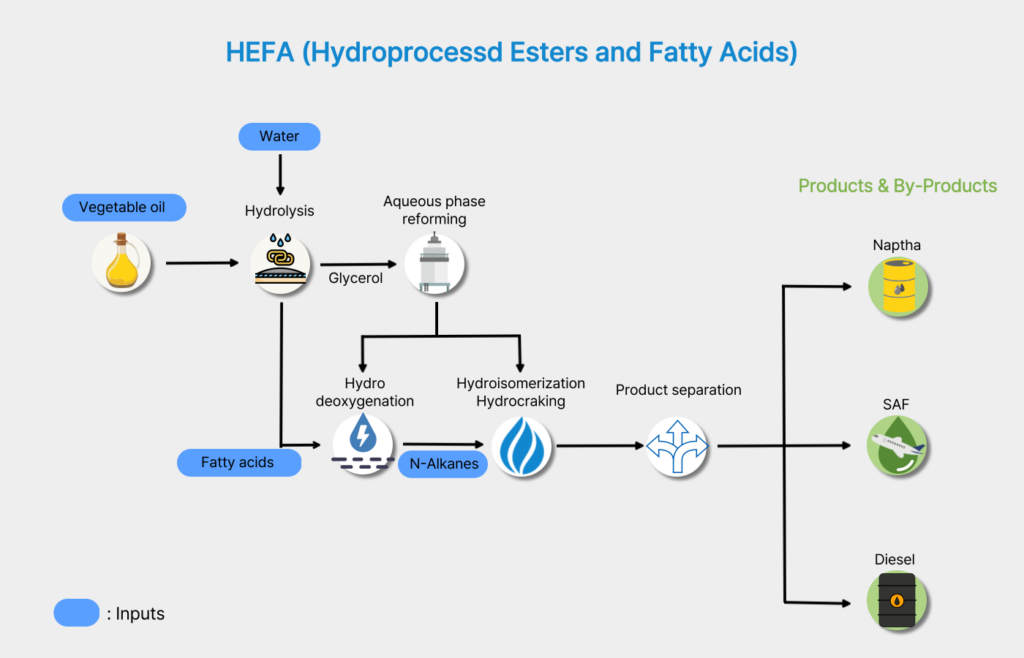

1) HEFA (Hydroprocessed Esters and Fatty Acids)

The most mature and widely used SAF pathway (80% market share), HEFA uses used cooking oil, animal fats, and vegetable oils. These are refined and hydroprocessed using catalysts and hydrogen, followed by separation and purification. While efficient and cost-effective, HEFA may raise food-vs-fuel concerns due to the use of edible oils.

2) FT(Fischer-Tropsch)

This process gasifies biomass (e.g., wood or agricultural residues) to generate syngas (CO + H₂), which is then converted into liquid fuels using Fe or Co catalysts. FT can also use captured CO₂ and green hydrogen, making it a path to carbon-neutral fuels. However, it is more technologically complex and costly than HEFA.

3) ATJ(Alcohol-to-Jet)

ATJ converts biomass-derived alcohols (ethanol or butanol) into jet fuel via dehydration, oligomerization, and hydrogenation. Although versatile in feedstock options, it requires large amounts of biomass and is less energy-efficient.

4) PtL(Power-to-Liquid)

This next-generation SAF pathway uses green hydrogen (from renewables) and captured CO₂ (via DAC or industrial sources) to produce syngas, then SAF. While offering full fossil fuel independence and theoretical carbon neutrality, PtL currently has the highest production cost due to its technological and infrastructure demands.

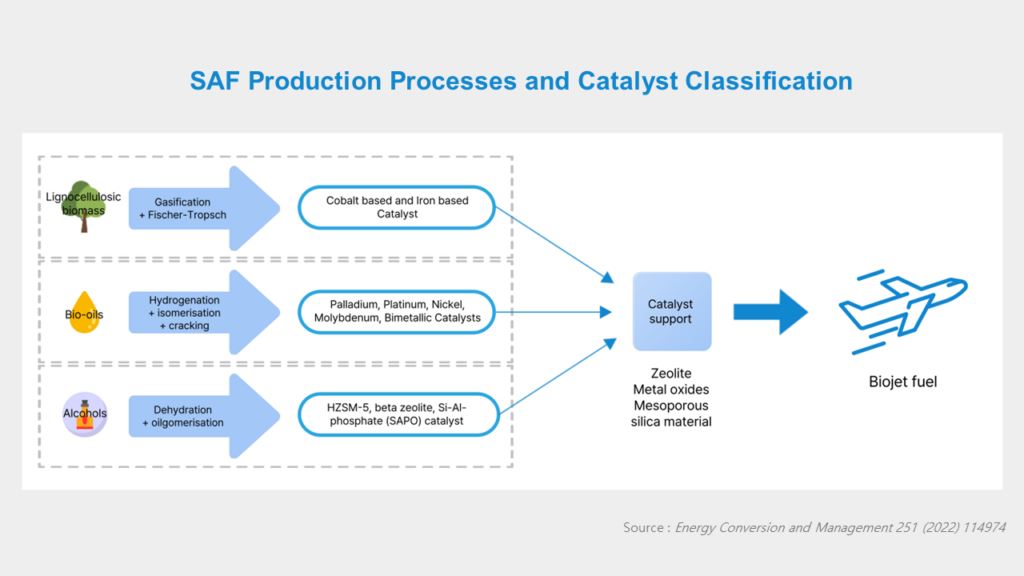

Catalysts: The Heart of SAF Production

Each SAF pathway requires specialized catalyst technologies:

- HEFA : Hydrogenation catalysts

- FT : Syngas conversion catalysts

- PtL/ATJ : CO₂ reduction and alcohol conversion catalysts

Heesung Catalysts leverages decades of experience in refining, petrochemical, and environmental catalyst technologies to support SAF production. Our portfolio includes hydroprocessing catalysts, syngas conversion catalysts, and CO₂-to-fuel catalysts. We also offer advanced catalyst control technologies to maximize conversion efficiency, selectivity, and durability tailored to each SAF process.

Global Shift Toward SAF

The SAF transition is no longer optional.

- The EU’s ReFuelEU initiative mandates a 2% SAF blend starting in 2025, targeting 70% by 2050.

- South Korean airlines have begun SAF trial flights on routes to Japan, with full-scale international adoption set for 2027.

Heesung Catalysts is committed to advancing SAF catalyst technology through continuous innovation, driving the transition toward carbon-neutral aviation.