Catalysts: Unlocking New Possibilities in Greenhouse Gas Reduction

2025.04.01

As the global community tightens climate regulations, countries and corporations alike are being held to stricter standards for greenhouse gas (GHG) emissions. From the implementation of the Carbon Border Adjustment Mechanism (CBAM) to mandatory ESG disclosures, companies must now take active responsibility for the carbon footprint of their operations and products.

Although Korea has pledged to reduce 37.5 million tons of GHG emissions abroad by 2030 through international carbon reduction projects, progress has fallen short of this goal. With domestic challenges and global regulations intensifying simultaneously, a proactive and strategic response has become more crucial than ever.

Why Greenhouse Gases Are a Global Threat

Greenhouse gases absorb thermal radiation, trapping heat and raising Earth’s surface temperature—an effect that underpins modern climate change. Since the Industrial Revolution, human activity has dramatically increased atmospheric GHG levels, destabilizing the global climate system.

The most common GHGs include carbon dioxide (CO₂), methane (CH₄), nitrous oxide (N₂O), and fluorinated gases (HFCs, PFCs, SF₆), with CO₂ accounting for more than 75% of total emissions. CO₂ primarily results from burning fossil fuels for electricity generation, industrial production, transportation, and heating.

The Intergovernmental Panel on Climate Change (IPCC) warns that unchecked GHG accumulation could trigger sea level rise, ecosystem disruption, and global food insecurity—posing a direct threat to human survival.

Global GHG Reduction Policies and How Companies Are Responding

Stronger Global Frameworks

The 2015 Paris Agreement united the world under the shared goal of limiting global temperature rise to 1.5°C above pre-industrial levels. Since then, nations and institutions have introduced a range of climate-related laws and policies.

The EU’s CBAM imposes carbon tariffs on high-emission imports, directly impacting global supply chains. High-carbon products are losing competitiveness, and businesses must now decarbonize production to maintain market access. The U.S. Inflation Reduction Act (IRA) is also accelerating the transition to clean energy.

National Policies and Emission Management

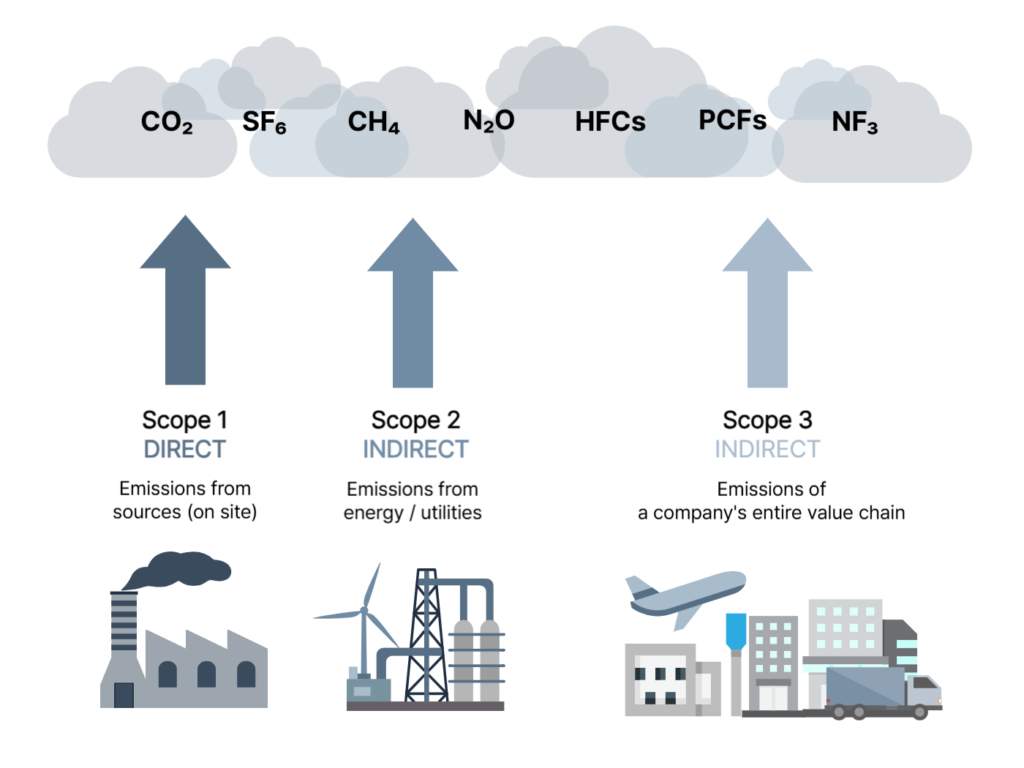

South Korea is also committed to achieving carbon neutrality by 2050, implementing policies such as the Korea Emissions Trading Scheme (K-ETS) and the Target Management System to encourage corporate greenhouse gas (GHG) reductions. Recently, there has been a growing emphasis on not only reducing total emissions but also managing emissions comprehensively across Scope 1, 2, and 3, which encompass both direct and indirect sources.

As a result, the government and evaluation agencies now place greater importance on how accurately companies can measure, report, and reduce their emissions. This capability is considered a critical criterion for ESG evaluations, access to green finance, maintaining global supply chain competitiveness, and ensuring long-term business sustainability.

Today, companies are beginning to view GHG management not as a cost burden, but as a strategic investment essential to securing future competitiveness. Furthermore, carbon reduction technologies and strategies—such as Carbon Capture, Utilization and Storage (CCUS), the hydrogen economy, and eco-friendly catalyst technologies—are opening up new opportunities for business growth.

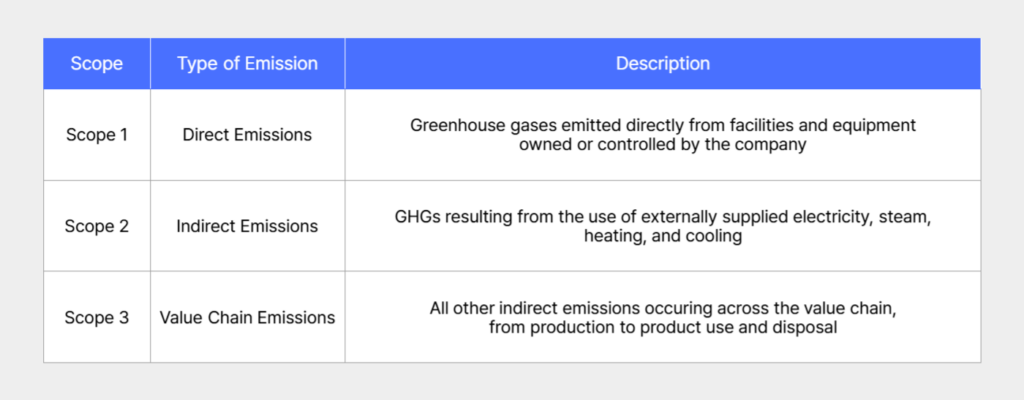

Understanding Scope 1, 2, and 3 Emissions

The internationally recognized framework of Scope 1, 2, and 3 emissions is designed to help organizations systematically manage their greenhouse gas (GHG) emissions. At its core, this classification clarifies where and how emissions are generated throughout a company’s operations and value chain.

This structure enables businesses to define their emissions responsibilities more clearly and serves as the foundation for developing effective reduction strategies. In recent years, particular attention has been given to Scope 3 emissions, which account for indirect emissions across the entire value chain. As a result, there is a growing need for cross-industry collaboration and ecosystem-wide responses to reduce GHG emissions comprehensively.

High-GWP Greenhouse Gases from Industrial Sources

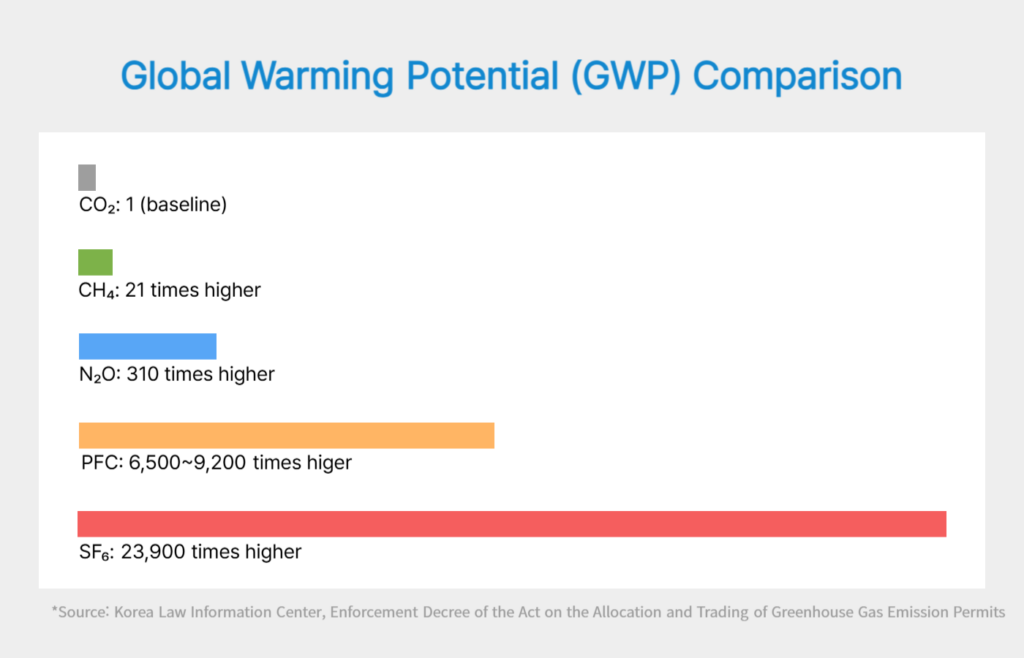

In industrial settings, emissions are not limited to carbon dioxide (CO₂); various high global warming potential (GWP) gases that have a much greater climate impact are also released.

Semiconductor and Display Manufacturing

Processes such as plasma cleaning and semiconductor circuit fabrication often use potent GHGs like nitrous oxide (N₂O), perfluorinated compounds (PFCs), sulfur hexafluoride (SF₆), and nitrogen trifluoride (NF₃). These gases have GWPs significantly higher than CO₂, and if released without proper treatment, they can severely contribute to climate change.

For instance, PFCs are essential in semiconductor etching but have 6,500 to 9,200 times the warming effect of CO₂, while SF₆ has a GWP of 23,900. As advanced manufacturing industries continue to expand, the use of such gases increases—making effective mitigation technologies vital for maintaining industrial competitiveness.

Power Generation, CNG/LNG Engines, and LFG Systems

Facilities such as dual-fuel engines, landfill gas (LFG) systems, and biogas plants are major sources of methane (CH₄) emissions—a high-GWP gas with 21 times the warming potential of CO₂. Methane is also released during fossil fuel extraction and transport, agricultural activities, and waste treatment, accounting for approximately 16% of global GHG emissions.

If left uncontrolled, these high-GWP gases can significantly increase national GHG inventories and expose companies to regulatory and reputational risks. Therefore, CO₂-focused strategies alone are insufficient. It is increasingly urgent to develop industry-specific technologies and solutions to effectively manage and reduce high-GWP gas emissions.

The Role of Catalysts in Addressing the Climate Crisis

Catalysts are emerging as a key technology in the fight against climate change. They play a critical role in either converting greenhouse gases into harmless substances or maximizing fuel combustion efficiency to reduce emissions.

PFC Decomposition Catalysts

These catalysts are designed to safely break down perfluorocarbons (PFCs)—potent greenhouse gases emitted during semiconductor and display manufacturing—at high temperatures. Advanced PFC decomposition catalysts can operate at lower temperatures than traditional plasma-based systems, offering enhanced durability and reduced maintenance costs for environmental control facilities.

Such technologies are essential for ensuring the sustainable growth of the semiconductor and display industries and enhancing the global competitiveness of Korea’s advanced manufacturing sector.

N₂O Decomposition Catalysts

N₂O decomposition catalysts convert nitrous oxide (N₂O)—a gas with a global warming potential approximately 310 times greater than CO₂—into nitrogen and oxygen. Even in small quantities, N₂O significantly contributes to climate change.

These catalysts are effective in chemical and semiconductor industries, especially in nitric acid production processes, and serve as a strategic solution to address carbon border tariffs and international environmental trade regulations.

Methane Oxidation Catalysts

Methane oxidation catalysts are used in CNG/LNG engine aftertreatment systems, dual-fuel engines, power plants, landfills, and biogas facilities. They convert high concentrations of methane (CH₄)—a potent greenhouse gas—into carbon dioxide, thereby reducing overall emissions.

These catalysts offer high conversion efficiency even at low temperatures, contributing to both cost savings and regulatory compliance. As an effective tool for short-term GHG reduction, this technology also aligns with international initiatives such as the Global Methane Pledge (GMP).

GHG Reduction Catalysts

Greenhouse gas reduction catalysts are engineered for high activity at low temperatures, enabling the removal of multiple pollutants simultaneously, including nitrous oxide (N₂O), carbon monoxide (CO), and volatile organic compounds (VOCs). These catalysts are durable, resistant to poisoning, and regenerable, ensuring cost-effective and long-term operation.

1. Regulatory Compliance & Risk Management: Proactively responding to tightening domestic and international environmental regulations to minimize legal and financial risks.

2. Cost Efficiency: Reducing energy consumption and maintenance costs to achieve economic benefits and operational savings.

3. Enhanced Corporate Image: Strengthening ESG ratings and brand trust through environmentally responsible management practices.

4. New Business Opportunities: Securing carbon credits and expanding into emerging clean technology markets.

Corporate Responsibility and Opportunity in Overcoming the Climate Crisis

The climate crisis is no longer a future threat—it is a present and pressing global challenge. For companies, greenhouse gas (GHG) reduction is now a strategic imperative that goes beyond regulatory compliance. It is essential for ensuring sustainable growth, enhancing global competitiveness, and meeting expanding environmental regulations.

The climate crisis is no longer a future threat—it is a present and pressing global challenge. For companies, greenhouse gas (GHG) reduction is now a strategic imperative that goes beyond regulatory compliance. It is essential for ensuring sustainable growth, enhancing global competitiveness, and meeting expanding environmental regulations.

Heesung Catalysts supports businesses by providing high-performance GHG reduction catalysts that enable them to reduce emissions, respond proactively to policy changes, and stay ahead in the transition to a low-carbon economy. Through early adoption of clean technologies and innovative solutions, companies can minimize regulatory risks, boost energy efficiency, and unlock new business opportunities in the clean tech market.

Heesung Catalysts is committed to being a trusted partner on this journey, delivering catalyst innovations that help build a more sustainable, carbon-neutral future.