Waste Reimagined : Biogas, the Energy Revolution for Carbon Neutrality

2025.03.20

“What if the food waste you threw away today could heat your home tomorrow?”

There is a technology that transforms food waste and livestock manure—materials we discard every day—into a valuable source of renewable energy. That technology is biogas.

As global temperatures continue to rise and the limitations of fossil fuels become more evident, biogas has gained attention as a solution that recovers energy from waste. As a type of biofuel, biogas is increasingly recognized as an effective alternative that addresses two critical challenges at once: waste management and clean energy production.

Biofuels are produced by breaking down and fermenting biomass—such as agricultural byproducts, forestry residues, livestock waste, and food scraps. They are used in various forms, including biodiesel, bio-heavy oil, bioethanol, biogas, and sustainable aviation fuel (SAF). Just as SAF contributes to carbon neutrality in the aviation industry, biogas plays an essential role in the global energy transition.

How Is Biogas Produced?

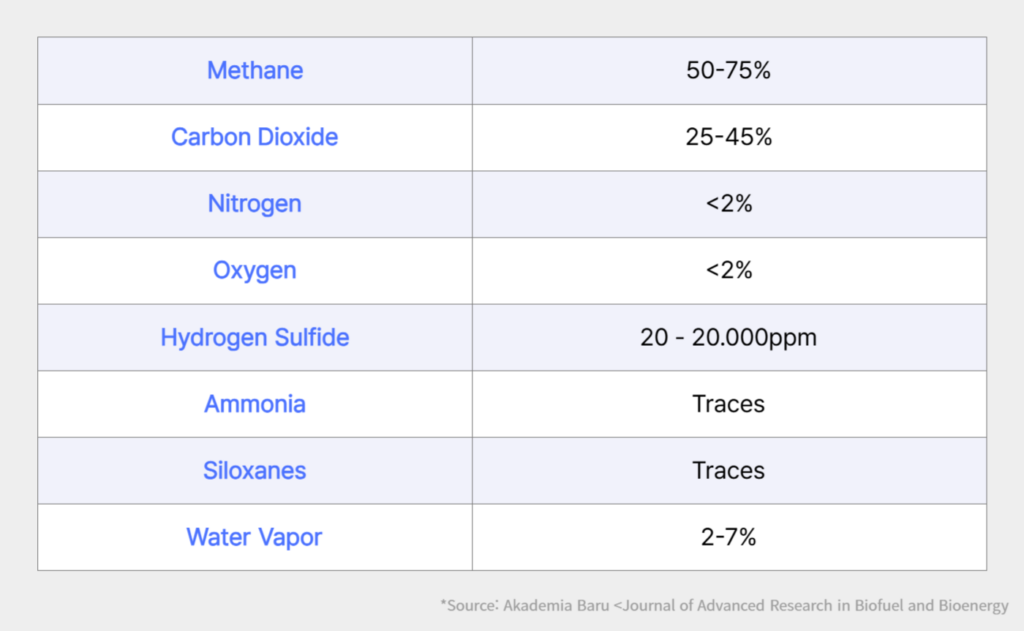

Biogas is a mixed gas generated through anaerobic digestion, a biological process in which microorganisms break down organic matter in the absence of oxygen. It is primarily composed of methane (CH₄) and carbon dioxide (CO₂), along with trace amounts of nitrogen (N₂), oxygen (O₂), hydrogen sulfide (H₂S), ammonia (NH₃), and water vapor (H₂O) (see Table 1).

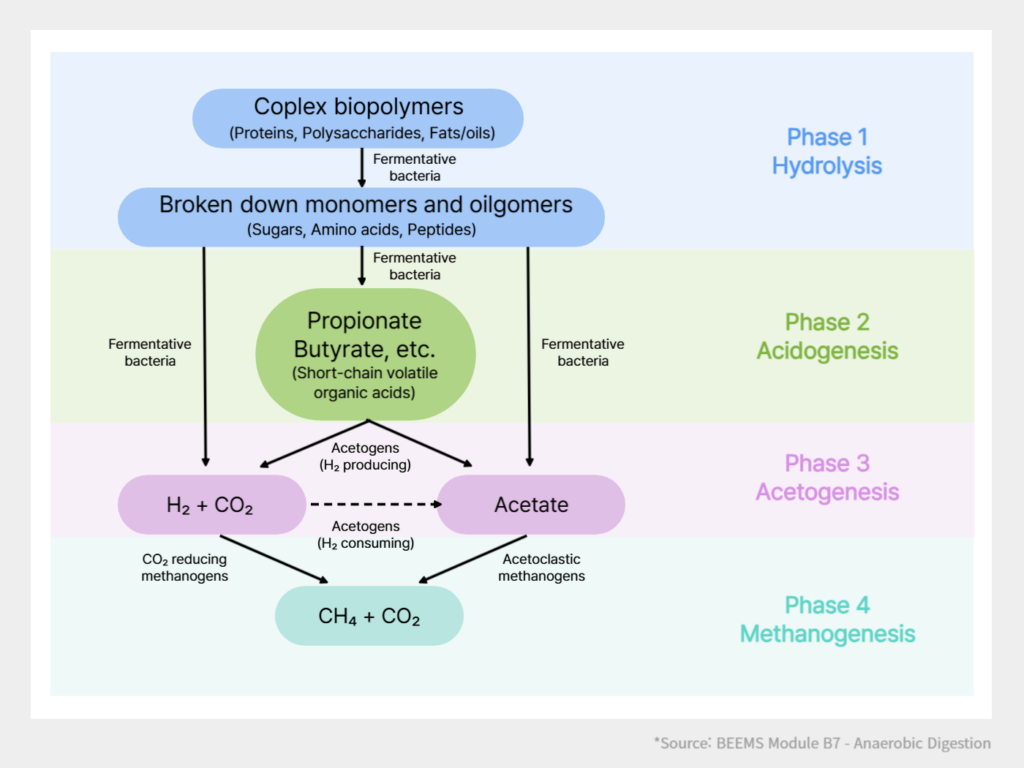

Stages of Anaerobic Digestion for Biogas Production

1. Hydrolysis

Complex organic compounds such as carbohydrates, proteins, and fats are broken down into simpler molecules.

2. Acidogenesis

The hydrolysis products are converted into volatile fatty acids, alcohols, ammonia, carbon dioxide, and hydrogen.

3. Acetogenesis

Intermediates from the acidogenesis phase are further broken down into acetic acid, CO₂, and hydrogen.

4. Methanogenesis

In the final stage, methanogenic bacteria convert acetic acid, hydrogen, and carbon dioxide into methane and CO₂.

This process takes place in specially designed digesters, also known as biogas plants, where organic feedstock undergoes a complete fermentation cycle through all four stages. At each stage, different types of microorganisms are responsible for breaking down the material, and their biological activity is the key driver of biogas production.

One of the most distinctive advantages of biogas is its feedstock versatility. Nearly all types of organic matter can be used as fuel—except for certain plant-based materials like wood, which are high in lignin or cellulose content and are more resistant to decomposition. This broad adaptability allows biogas to be produced without relying heavily on dedicated energy crops, unlike other biomass-based fuels such as biodiesel or bioethanol.

According to Mordor Intelligence, the global biogas market is projected to grow at a compound annual growth rate (CAGR) of 4.51% from 2025 to 2030. As global electricity demand continues to rise—driven by population growth, industrialization, and urbanization—the value of biogas as a reliable energy source is increasing steadily.

The International Energy Agency (IEA) also forecasts that the global electricity demand growth rate between 2024 and 2025 will reach its highest level in two decades. The growth rate is expected to hit 4% in 2024, the highest since 2007, with similar trends continuing into 2025.

Amid this rapidly rising electricity demand and global shift toward renewable energy, biogas is gaining recognition as a key solution for a sustainable energy transition in the power sector. The convergence of urgent clean energy needs and accelerating demand highlights the critical role of biogas in shaping the future of energy.

From Waste to a Multi-Purpose Energy Solution

City Gas Supply

Biogas can be purified through an upgrading process, where methane is extracted and refined, and then injected directly into city gas pipelines. In South Korea, this application has been commercialized since 2012 following revisions to the City Gas Business Act and the establishment of quality control standards. A representative example is the livestock waste utilization facility in Hongcheon, Gangwon Province, which converts local livestock manure into biogas and supplies it as city gas.

Electricity and District Heating

Biogas is used in combined heat and power (CHP) plants to generate both electricity and heat simultaneously. At the Seonam Water Recycling Center in Seoul, biogas produced from wastewater treatment is used to generate electricity, while the resulting heat is supplied for district heating, creating a closed-loop energy system that enhances efficiency and reduces greenhouse gas emissions.

CNG Fuel for Vehicles

Biogas is also used as a fuel for compressed natural gas (CNG) vehicles. At the Sangri BIO Station in Daegu, biogas derived from food waste and sewage sludge is refined and supplied as vehicle fuel. This is a prime example of reducing dependence on fossil fuels and promoting a circular economy.

Hydrogen Production and Fuel Use

Technologies are advancing to extract hydrogen from biogas for use in hydrogen fuel cell vehicles. The Chungju Bio-Green Hydrogen Station reforms biogas from organic waste to produce hydrogen, which is then supplied as fuel for hydrogen-powered vehicles. This is considered a pivotal step toward a renewable hydrogen economy..

Green Methanol Production

Technologies are also being developed to produce clean methanol from methane extracted from biogas. This methanol can be used as a marine fuel, attracting attention as a sustainable alternative in response to tightening environmental regulations by the International Maritime Organization (IMO).

In this way, biogas is evolving beyond a waste treatment method into a versatile clean energy source, playing a vital role in the transition toward a carbon-neutral society.

The Value of Biogas as a Renewable Energy Source

Biogas is a renewable energy resource that offers technological, environmental, and economic advantages. One of its most significant strengths is its ability to provide a stable and continuous energy supply year-round. Unlike solar and wind power, which fluctuate based on weather and time of day, biogas can deliver consistent output—making it a key component in a balanced renewable energy portfolio.

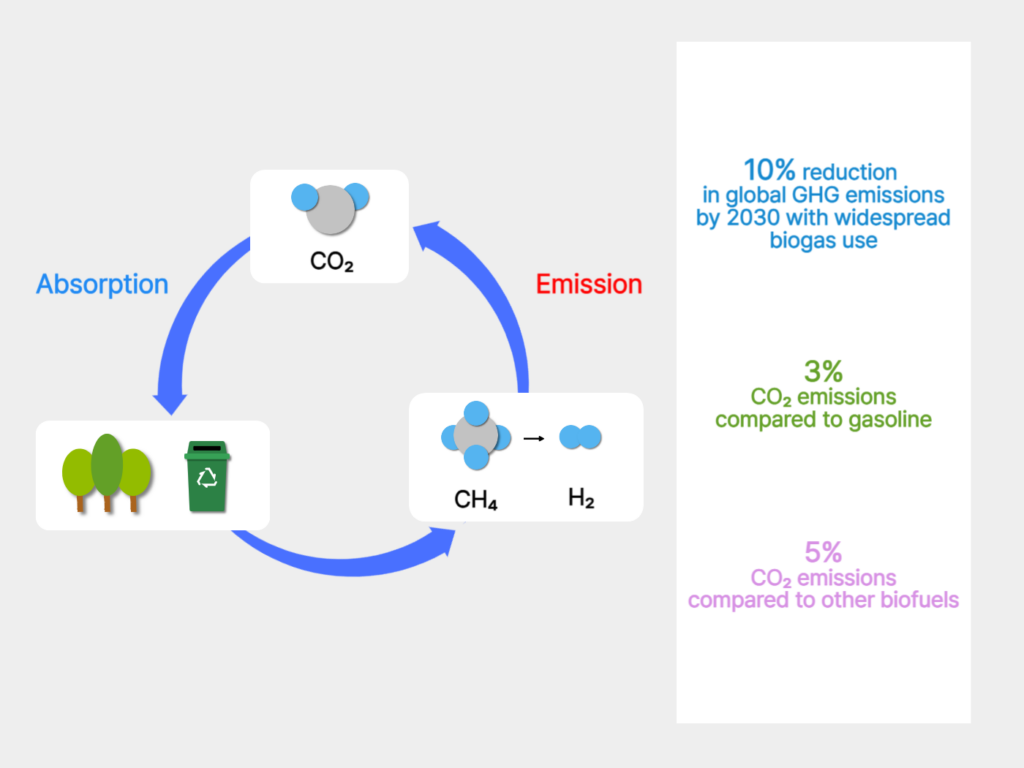

According to the World Biogas Association (WBA), over 10.5 billion tons of organic waste are generated globally each year. If even a portion of this waste were used for biogas production instead of being incinerated or landfilled, it could reduce global greenhouse gas emissions by up to 10% by 2030.

Biogas also demonstrates clear environmental benefits during its production and combustion. When burned, biogas emits only about 3% of the CO₂ compared to gasoline combustion. Even when compared to other biofuels, its CO₂ emissions are as low as 5%, making it one of the cleanest bio-based energy sources available. Moreover, the CO₂ generated during biogas production can be captured and reused as agricultural fertilizer or industrial gas, making biogas a virtually carbon-neutral fuel.

In line with these advantages, the South Korean government has set a target of producing 500 million Nm³ of biogas annually by 2026, which would involve processing 5.57 million tons of organic waste, replacing KRW 230 billion worth of fossil fuels, and reducing 1 million tons of greenhouse gas emissions per year.

To meet this goal, the government plans to implement mandatory biogas production targets for the public sector by 2025 and for the private sector by 2026. In addition, it will support the expansion of integrated biogas facilities capable of processing multiple types of organic waste. Efforts will also be made to diversify biogas applications, such as supplying it to city gas networks, expanding hydrogen production infrastructure, and advancing clean methanol production—to enhance the economic viability and real-world effectiveness of biogas as a future-ready energy source.

The Future of Biogas: What Should We Prepare For?

The biogas industry is expected to play a crucial role in achieving carbon neutrality and building a circular economy. However, to realize its full potential, technological innovation aimed at improving production efficiency and cost competitiveness is essential.

Key areas for development include enhancing the reactivity of anaerobic digestion, advancing biogas upgrading technologies, and converting by-products such as digestate into useful resources. In this process, the application of catalyst technologies can significantly increase reaction speed, reduce energy consumption, and improve biogas purity, contributing to higher overall efficiency.

In addition to improving production processes, the scope of catalyst applications should be expanded to maximize the value of biogas across a range of energy solutions.

Currently, the biogas sector is largely driven by public initiatives, but in the long term, active participation and investment from private enterprises will be essential. Developing profitable business models and offering incentives to attract private capital will be key to sustainable industry growth.

It is also important to address community concerns about biogas facilities and to actively promote the environmental and economic benefits of biogas to the public. Raising awareness and fostering social acceptance will be just as important as technological progress in shaping the future of the biogas industry.

Enhancing the Value of Biogas with Catalyst Technologies

Catalyst technologies play a critical role in enhancing both the efficiency and value of biogas. One notable application is in the biogas upgrading process, where nickel-based catalysts are used to selectively remove carbon dioxide. This increases the methane concentration of the gas, allowing the upgraded biogas to reach a quality comparable to that of natural gas. As a result, it can be directly injected into the gas grid or used as a fuel for vehicles.

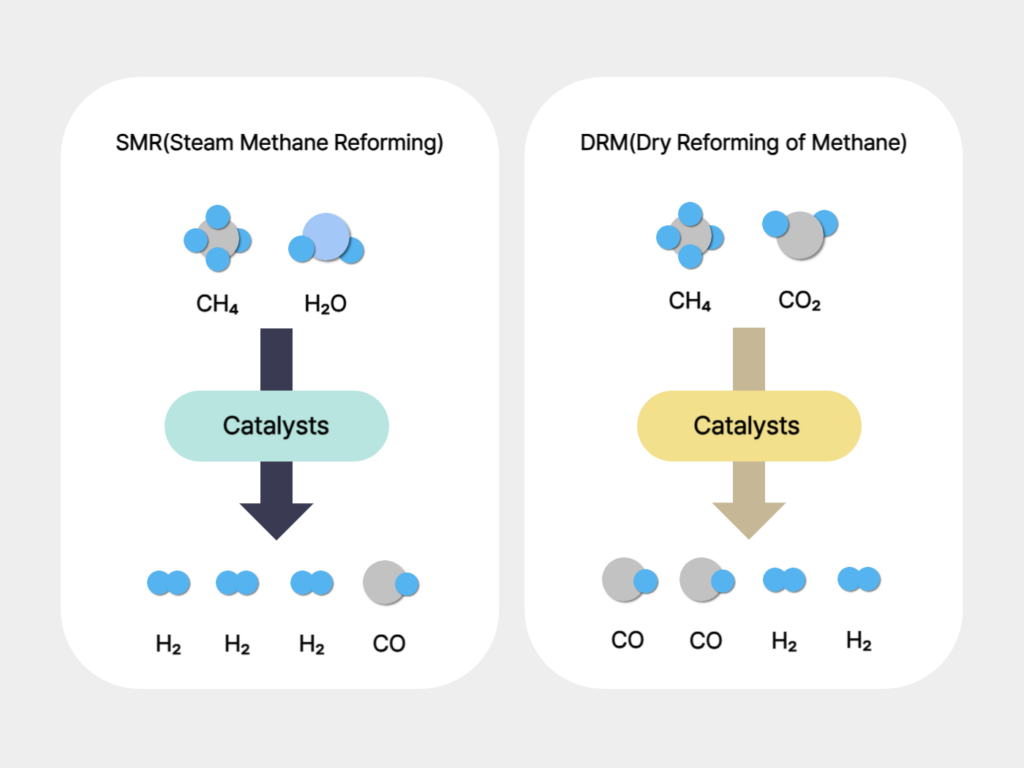

Biogas can also serve as a feedstock for hydrogen production through processes such as steam methane reforming (SMR) and dry reforming of methane (DRM). In the SMR process, biogas reacts with high-temperature steam to produce hydrogen, and nickel catalysts are used to accelerate the reaction. In the DRM process, methane and carbon dioxide are directly reacted to produce hydrogen and carbon monoxide, with either nickel or noble metal catalysts facilitating the conversion. The hydrogen generated through these methods, often referred to as bio-hydrogen, can be used in fuel cell vehicles, as industrial raw material, or for power generation.

In addition to hydrogen, biogas-derived methane and carbon dioxide can be converted into methanol or other synthetic fuels. This is typically done using copper-zinc catalysts. The resulting bio-methanol produces significantly fewer carbon emissions than fossil fuel-based methanol and is gaining attention as a clean fuel option for the shipping industry and chemical production. Its relevance continues to grow in light of increasingly strict environmental regulations, such as those imposed by the International Maritime Organization (IMO).

As catalyst technologies become more important across the entire hydrogen value chain, Heesung Catalysts is actively contributing by offering a wide range of solutions. These include catalysts for traditional SMR-based hydrogen production, as well as advanced catalysts for fuel cells and water electrolysis systems. Through these efforts, the company supports the transition to environmentally friendly hydrogen and contributes to the expansion of the hydrogen economy.

The continuous development of catalyst technologies is essential to unlocking the full potential of biogas. Not only do catalysts improve reaction rates and energy efficiency, but they also enable the production of higher-purity fuels, expanding the range of biogas applications. With new catalysts under development, both the economic viability and environmental impact of biogas are expected to improve significantly. Recognizing the growing importance of catalysts in hydrogen production, methanol synthesis, and other key processes, Heesung Catalysts remains committed to delivering high-efficiency, durable catalytic solutions that advance industrial growth and help achieve global carbon neutrality.