Key to the Clean Hydrogen Era: Ammonia Cracking Catalyst Technology

2024.12.26

Heesung Catalysts Leads Next-Generation Hydrogen Technology, Winning the KHNE Outstanding Research Paper Award

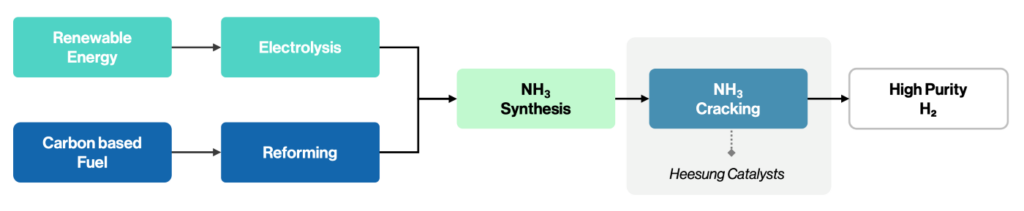

As the global energy market transitions toward carbon neutrality, hydrogen (H₂) is emerging as a next-generation energy source. With high energy efficiency and zero greenhouse gas emissions, hydrogen is a key driver of future energy systems. However, unlocking its full potential requires overcoming the challenges of efficient storage and transportation.

Pure hydrogen has low volumetric energy density, making high-pressure storage or cryogenic liquefaction essential—both of which require significant infrastructure investment. To address these challenges, ammonia (NH₃) is gaining attention as a viable alternative.

Ammonia: The Game-Changer for Hydrogen Transport

Ammonia remains a stable liquid at low pressure and ambient temperature, offering high hydrogen storage density while leveraging existing infrastructure. Storing and transporting clean hydrogen in ammonia form—produced in regions with abundant renewable energy—is opening new frontiers in the global hydrogen supply chain.

One of the biggest technical challenges in this process is the cracking of ammonia back into hydrogen. Traditionally, this reaction requires high temperatures, but for practical commercialization, achieving high conversion rates and long-term stability at lower temperatures is crucial.

What Sets Heesung Catalysts’ Ammonia Cracking Technology Apart?

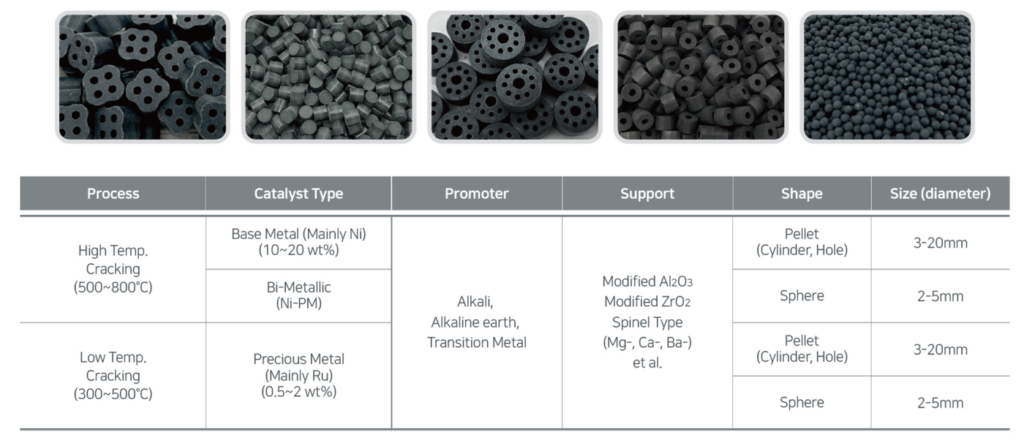

Heesung Catalysts has developed innovative solutions to overcome the technical challenges of ammonia cracking. By leveraging nano-structure control, surface modification, promoter incorporation, and metal loading techniques, Heesung Catalysts provides products that are optimized for various operating environments.

A prime example is the low-temperature ruthenium (Ru)-based catalyst, which has been designed with optimized ruthenium dispersion and promoter technology, ensuring high reaction rates and stability even in low-energy environments. Additionally, this catalyst is compatible with various structural configurations, including spherical (Sphere), monolithic (Monolith), and metal foam (Metal foam) structures, enhancing durability and water resistance.

For high-temperature applications, nickel (Ni)-based catalysts utilize impregnation (Impregnation) and co-precipitation (Co-precipitation) metal loading techniques, enabling cost-effective production while improving efficiency. The high-performance nickel catalyst, with up to 40% metal content, exhibits high activity under both adiabatic (Adiabatic) and isothermal (Isothermal) cracker conditions, while simultaneously reducing operational costs.

Heesung Catalysts has established a comprehensive evaluation system, integrating kinetic modeling and advanced analytical techniques. By utilizing a range of reactors from laboratory-scale to full-scale industrial applications, Heesung Catalysts maximizes the performance and advantages of each catalyst, providing customized solutions tailored to customers’ specific operating conditions.

Heesung Catalysts Recognized for Innovative Technology

At the 2023 Korean Hydrogen & New Energy Society (KHNE) Fall Conference, Heesung Catalysts was awarded the Outstanding Research Paper Award for its study on hydrogen production through ammonia decomposition using ruthenium-based catalysts, demonstrating its excellence in catalyst design and manufacturing technology.

During the conference, Heesung Catalysts showcased a range of eco-friendly energy materials, including reforming catalysts and fuel cell electrode catalysts. The company also shared extensive research findings on methane reforming reactions and water-gas shift catalysts for carbon monoxide (CO) removal.

This recognition highlights Heesung Catalysts’ commitment to innovation and its role in advancing hydrogen economy technologies, reinforcing its leadership in sustainable catalyst solutions.

Presentation on “Hydrogen Production via Ammonia Decomposition on Ruthenium-Based Catalysts” (Photo: Heesung Catalysts)

Realizing a Sustainable Future with Ammonia Technology

Ammonia cracking catalyst technology is continuously evolving, addressing challenges such as enhancing hydrogen production efficiency, improving durability in extreme conditions, and advancing catalyst regeneration technologies. Heesung Catalysts is proactively tackling these challenges by refining catalyst design, enhancing evaluation techniques, advancing process simulation technologies, and strengthening mass production and quality control systems.

As the hydrogen economy expands, ammonia will play an increasingly vital role in global hydrogen supply chains. With large-scale infrastructure adoption on the rise, technological innovation and cost competitiveness are becoming key priorities. Heesung Catalysts is adapting to these industry shifts by developing customized catalysts and offering integrated process solutions, maximizing value for its customers.

Heesung Catalysts aims to go beyond catalyst manufacturing, positioning itself as a key partner in the hydrogen economy. Through continuous technological innovation and close collaboration with industry stakeholders, the company is committed to solving critical challenges in the energy sector and driving the realization of a sustainable hydrogen future.