Aniline Catalyst

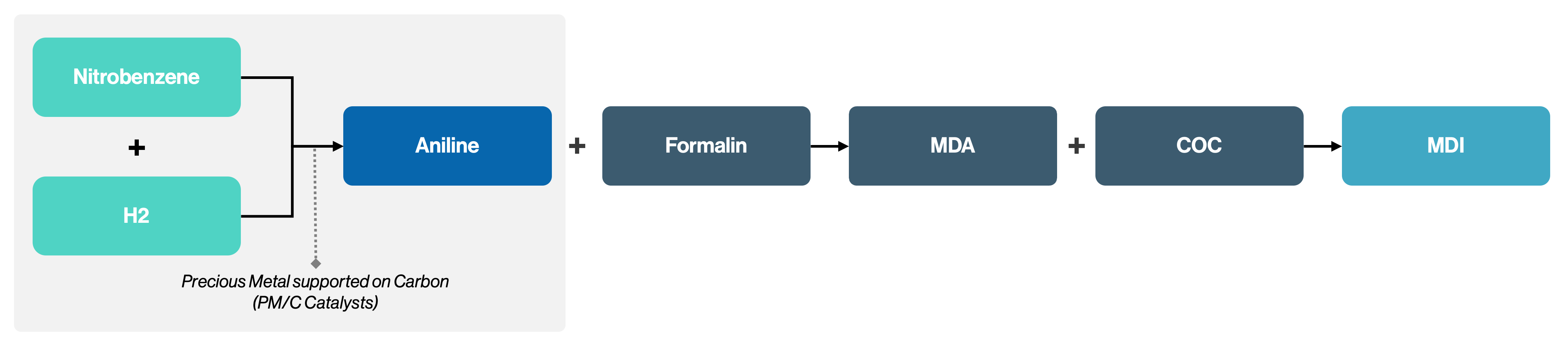

Precious metal carbon catalysts used in the aniline production process, a precursor to MDI (Methylene Diphenyl Disocyanate), a key raw material for polyurethane, require high hydrogenation reaction yields and selectivity. Heesung Catalysts’ precious metal carbon catalyst provides the optimal solution for producing aniline from nitrobenzene through hydrogenation.

MDI Manufacturing Process: Application of PM/C Catalyst

Aniline Catalyst Applications and Products

| Applicable Process | Catalyst Type | Form of Supply |

|---|---|---|

| Hydrogenation, Nitro Benzene for Aniline | Pd-promoters, Pd-Pt-promotors | Carbon powder (wet) or Slurry |

Heesung's Specialized Customer Technical Support

We do not simply sell catalyst products. Heesung Catalysts provides tailored technical support to ensure customers fully benefit from our specialized catalytic technologies. By providing optimal catalyst conditions to ensure that our catalysts perform at their best in a variety of processes. With over 40 years of accumulated experience, we enable improved catalyst performance, longer lifespan, and enhanced stability.